Ever wonder how we make our large band saw blades for sawmills? Here’s a quick overview on our manufacturing process!

Utilizing Advanced Band Saw Manufacturing Processes for Superior Results

We were the first to introduce water jet cutting to produce the tooth geometry on band saws. Tooth geometry is cut into the band saw blade by utilizing either a CNC laser or high powered CNC Water jet cutter. The geometry, thickness and other factors for a particular application are taken into consideration when deciding which manufacturing method is best to utilize. The water jet CNC machine features a dynamic cutting head to compensate for deflection and cuts at 50,000 psi’s, which allows for a precise cut of the saw’s teeth every time without heating or fracturing the steel.

Using Water Jetting for More Precise Results

Oleson Saw Technology was the first U.S. band saw manufacturer to develop variable pitch and depth band saws and today is the acknowledged expert in this technology. The use of the water jet in the manufacturing process allows accurate cutting of variable pitch and depth in the saws per the customers’ request.

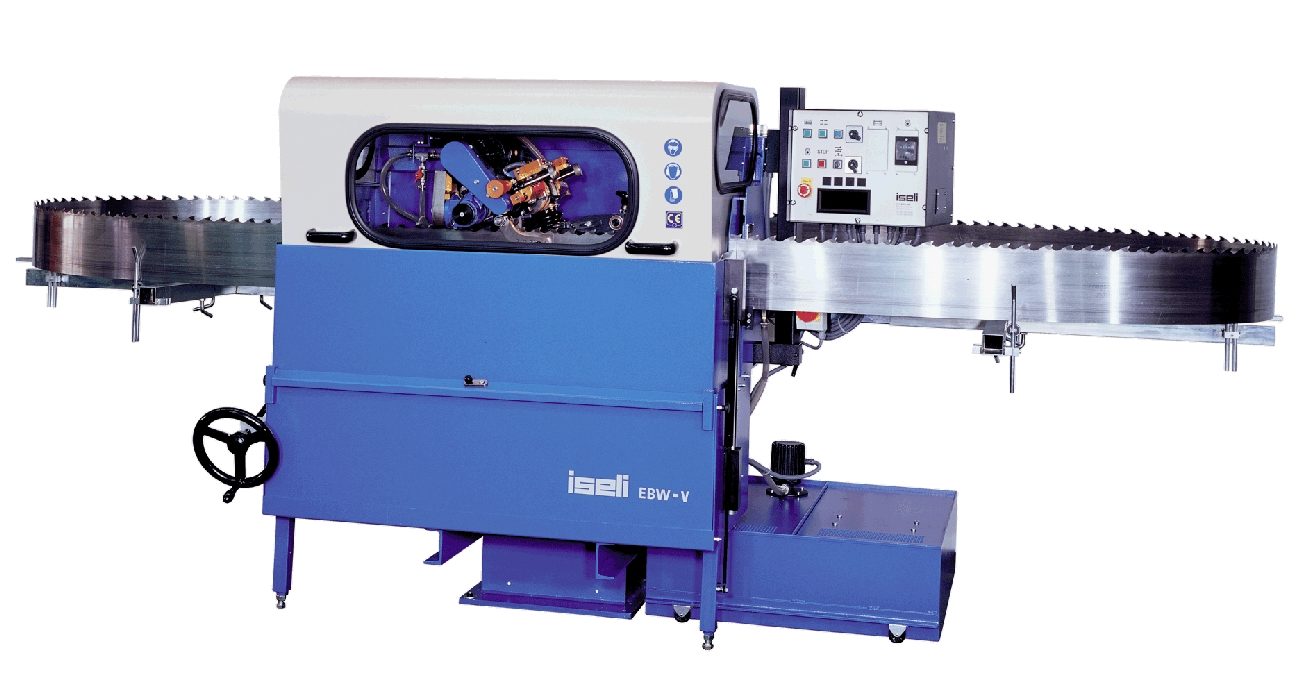

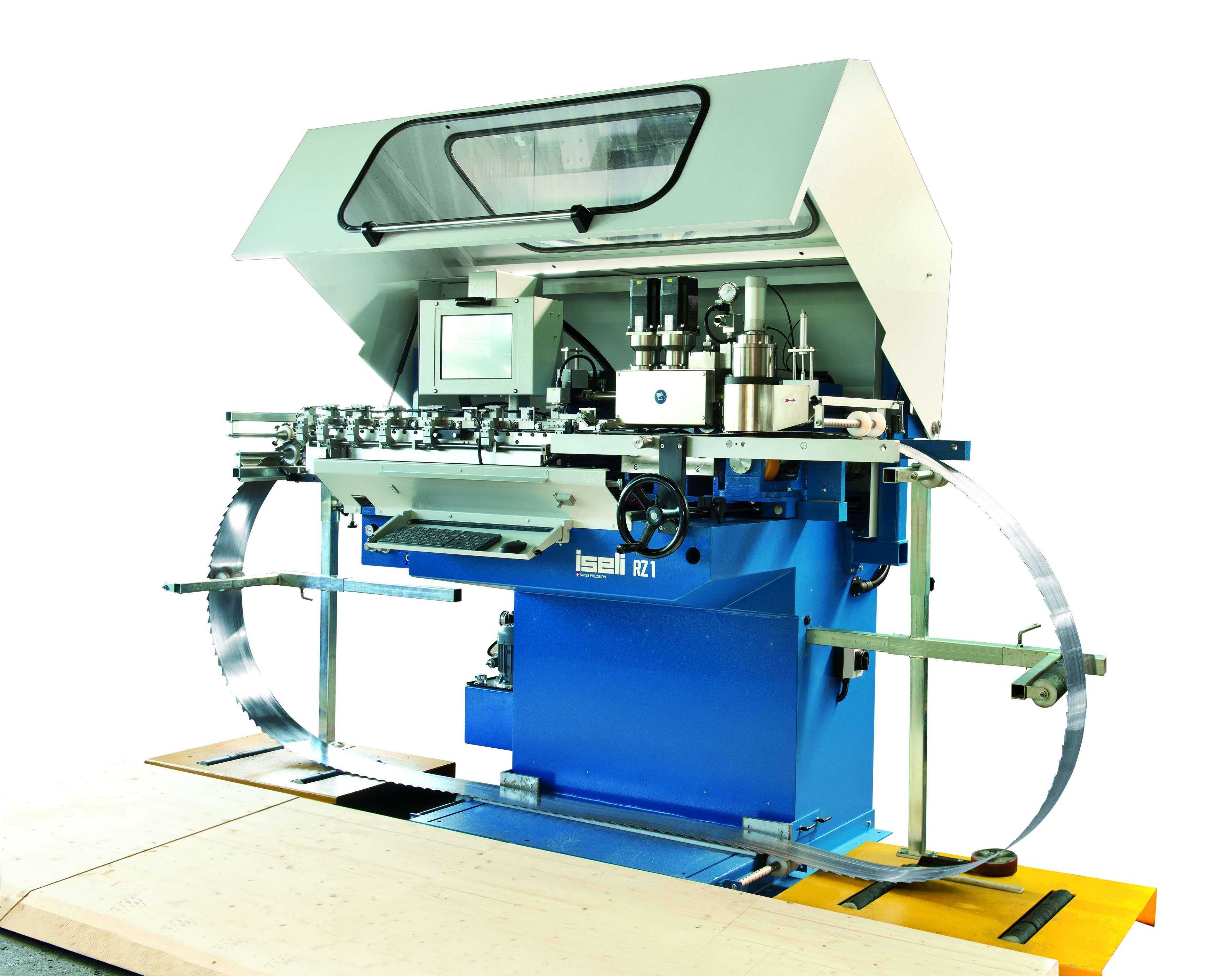

Setting Industry Standards for Band Saw Manufacturing With the Finest Tools and Brands Available — Iseli of Switzerland

In addition to being the only US distributor of the most modern line of saw filing equipment available, Iseli of Switzerland, we utilize Iseli equipment in the manufacturing of our band saws.

After benching and hand inspection, saws may be swaged and shaped on the Iseli STA. The hydraulic controlled Iseli STA is equipped with a tooth counter and auto stop feature making it fully automatic. An easy to use control panel and LCD screen simplifies operation and provides a digital display for short set-up time and highly precise results. The machine swages and shapes about 10 teeth per minute, allowing economic viability, and assuring the repeatability of a high standard product in saw after saw. The full automation of the STA has assisted us in being an efficient manufacturer. One person can operate multiple STA machines simultaneously, instead of only doing one operation at a time.

The sharpening of the saws then takes place on Iseli full flood CNC grinders. These fully automatic wet grinding machines allows the sharpening to take place in the most efficient and effective method. The tooth face and profile are ground using the same CNC program as the water jet and laser, making minimal steel removal and accurate profile per customer specifications. The machines are completely enclosed and the mist exhaust system provides maximum protection and safety while drastically reducing noise in the filing room. The ability to save tooth shapes in the machine’s memory paired with the CAD operating system also assists in a smooth manufacturing process of the band saws. OST’s cam machines were replaced by these automatic highly esteemed full flood CNC grinding machines to provide the best finish on Oleson saw blades to our customers.

For the Highest Quality Band Saw Products, Check out York Saw & Knife Co, Inc.

With help from Iseli and their state of the art equipment, the quality of finish and sharpness on our saws are unparalleled in either ready to tip, swaged tooth or stellite tipped saws. We are able to produce the highest quality of saws due to utilizing the best raw materials and equipment available in their manufacturing process.

When you use our band saws for your next job, you’re assured exceptional precision, durability and effective, lasting results. At York Saw & Knife Co, Inc., we believe in offering the best-value services and products. Call us today at 800-233-1969 to learn more about our band saw manufacturing process and related products.